A Comprehensive Guide to Understanding Litho Printing Methods

The globe of litho printing, a method originating from the late 18th century, is a remarkable blend of background, advancement, art and scientific research. This thorough guide will untangle the intricacies of this printing method, from the structure of litho inks to the challenges encountered in modern-day applications. As we venture into the intricacies of lithography, the importance of automation and sustainability in ensuring its future relevance ends up being progressively clear. Keep with us as we journey into the captivating realm of litho printing.

The Historical Advancement of Litho Printing

The historic trajectory of litho printing, a critical technology in the world of interaction, is a captivating story of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this strategy was originally an economical method of releasing staged jobs. Lithography, originated from the Greek words for 'stone' and 'to create', used a smooth rock surface to transfer pictures onto paper. The procedure advanced with the advent of the rotary press, which greatly enhanced productivity (litho printing). In the 20th century, the development of balanced out lithography transformed the sector, enabling automation of top quality prints. Each stage of litho printing's advancement showcases humanity's unrelenting quest of efficiency and top quality in visual communication.

Deciphering the Science Behind Litho Printing Inks

Moving on in the expedition of litho printing strategies, the emphasis now moves to the scientific research behind litho printing inks. The composition of these inks, their drying out process, and shade mixing strategies form the backbone of this complex art kind. Comprehending these elements is important to understanding the craft and attaining the desired print outcomes.

Composition of Litho Inks

In lithographic printing, the fundamental role of litho inks can not be overemphasized. The composition of litho inks differs depending on its objective, however typically, they include two main elements - pigments and cars. Pigments, the color-providing aspects, are carefully ground bits put on hold in the lorry, a fluid that lugs the pigment onto the printing surface area. The lorry is a complicated blend of resins, oils, and solvents, which influence the ink's drying out time, attachment, and gloss. In addition, different additives exist to improve specific residential or commercial properties like flow, drying out, and resistance to ecological effects. Each part plays a vital component in the last print's high quality, making the exact formula of litho inks a detailed scientific research.

Ink Drying Refine

From the composition of litho inks, interest transforms to the fascinating procedure of ink drying. The drying procedure is critical, as it affects the final print's top quality and longevity. 2 primary approaches are utilized in litho printing: oxidative drying and absorption. Oxidative drying out includes the ink responding with oxygen airborne to form a hard, completely dry film. This approach offers a durable finish, yet can be slower contrasted to absorption. Absorption, on the various other hand, involves the ink leaking right into the paper fibers, which is a much faster process yet can cause less lively shades. The option in between these techniques depends on elements such as print speed requirements, the paper kind utilized, and the preferred finish.

Color Mixing Strategies

While the drying process plays a vital role in litho printing, the scientific research of shade blending techniques holds equivalent significance. The scientific research behind litho printing inks also takes into account the openness of the ink, which impacts how colors overlay and mix.

The Art and Style Elements in Litho Printing

Litho printing breathes life right into art and design through its distinct components. The procedure entails producing a picture on a lithographic limestone plate or metal plate with a smooth surface area. The photo is after that printed onto a medium, normally paper, by moving the ink from home plate. What collections litho printing apart is its capacity to reproduce elaborate designs with high integrity, making the result almost similar to the original artwork. This is accomplished through making use of various line strategies such as hatching, cross-hatching, and stippling, which permit an array of tonal results. Litho printing accommodates a range of colors, allowing musicians to create lively and vibrant prints. This combination of accuracy and adaptability makes litho printing a preferred selection for lots of artists and developers.

Modern Applications of Litho Printing Strategies

Litho printing techniques have located his explanation extensive use in the contemporary industrial field. Its impact and significance remain to grow with the development of brand-new technologies and innovations in the field. This area will check out these contemporary applications and the transformative role they play in the printing sector.

Business Litho Printing Uses

In today's digital age, one could ask yourself about the importance of traditional printing approaches. Yet, litho printing stays an important part of the business field. High-volume printing jobs, such as the manufacturing of books, newspapers, and packaging, depend on litho printing for its ability to deliver remarkable photo quality and cost performance. The procedure, which includes transferring a tattooed image from a plate onto a rubber blanket and after that to the printing surface area, provides unparalleled uniformity. This makes it optimal for tasks calling for a large print run. Litho printing additionally offers a broad shade spectrum, remarkable to that of electronic printing. This makes it the best selection for tasks that require lively, premium shade reproduction.

Technologies in Litho Printing

Pushing the borders of typical methods, modern-day improvements have actually sustained a host of innovations in litho printing. These developments have not just boosted the quality and performance of litho prints but additionally increased its application scope. One popular growth is digital litho printing, which integrates the virtues of digital modern technology with litho's high-grade result. This crossbreed version offers faster setup times, reduced waste, and makes it possible for on-demand printing. One more remarkable innovation is the introduction of eco-friendly inks. These inks, made from veggie or soy-based remedies, have actually dramatically decreased the industry's environmental influence. litho printing. Additionally, the development of innovative plate technology has streamlined the printing procedure, leading to sharper photos and enhanced shade fidelity. These innovations underscore the enduring significance of litho printing in the modern-day world.

Checking out the Refine of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

Despite the precision and practice that litho printing happily supports, it is not without its collection of contemporary obstacles. Digital litho printing allows for affordable brief runs and very easy personalization, resolving the concern of variable information. Thus, while there are difficulties, the litho printing market is proactively adapting to fulfill them head-on, ensuring its relevance in the future.

Verdict

Finally, litho printing, with its rich history and scientific details, holds a considerable area in the print market. As the overview discloses, it's a synthesis of art and innovation, with modern-day innovations ensuring its relevance. The sector faces difficulties that call for ingenious solutions, with an emphasis on automation and sustainability. The future of litho printing hinges on its capacity to adapt to these altering demands, attesting its long-lasting worth in a developing market.

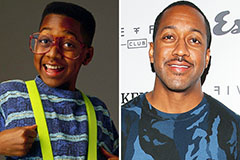

Jaleel White Then & Now!

Jaleel White Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!